JMZ stainless steel self-priming pump

Basic Info

Model No.: BODA-124

Product Description

JMZ stainless steel self-priming pump overview

Stainless steel self-priming pump JMZ, FMZ type adopts new mechanical seal assembly, safety explosion-proof, long-term leak-proof, suitable for conveying -35 degrees +80 degrees of various alcohol, beverage, dairy, pharmaceutical, gasoline, solvent oil, syrup, etc. Suction times over 40 degrees will be significantly reduced). JMZ, FMZ stainless steel self-priming pump has the characteristics of compact structure, simple operation, small size, light weight, stable performance, no need for bottom valve, no need for irrigation during start-up, JMZ, FMZ stainless steel self-priming pump after replacing 3-4 parts It can be used to transport thick liquid, acid, alkali, salt and other liquids. JMZ, FMZ stainless steel self-priming pump

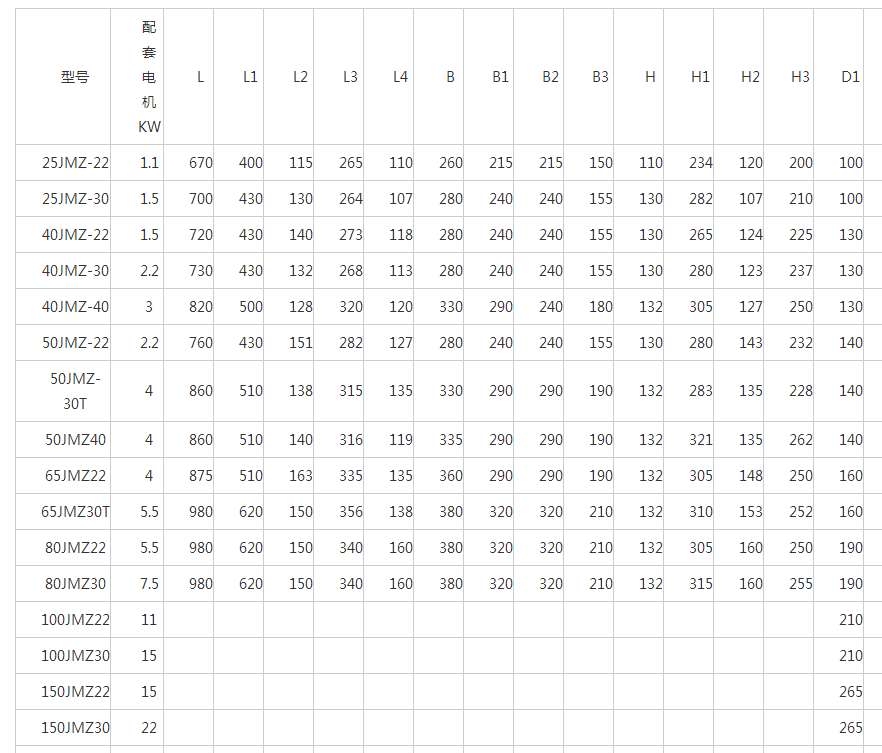

Performance range:

The flow rate is 3m3/h-100m3/h

Head is 18m-14m

The diameter is 25mm-150mm

Model meaning of JMZ stainless steel self-priming pump

Example: 40 J M Z - 30 T

40: Import caliber (mm)

J : J is the wine pump, F is the acid resistant pump

M : M stands for high quality stainless steel

Z : Z is self-priming, T is mobile, G is fixed

30: Head (m)

T : T: indicates the export or flow of special requirements

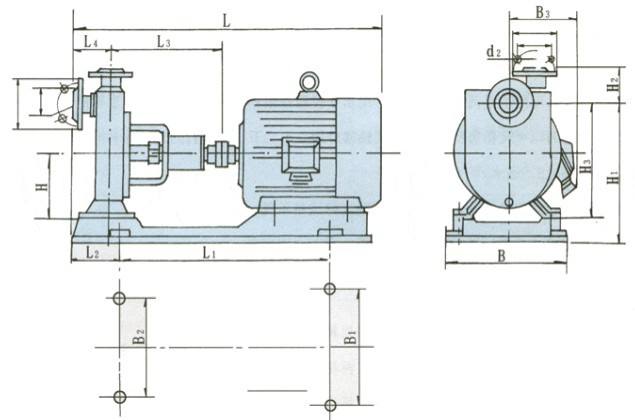

installation

1. The pump can be used according to the "Pump Profile Mounting Dimensions" to determine the base and determine the foot bolts. However, it is good to wait until the pump is delivered to the present sound and then carry out the construction according to the size of the base.

2, the pump is installed on the foundation, the level of the unit can be adjusted with the horn, the level of the motor shaft will be checked with the level meter, the concentricity of the pump shaft and the motor shaft should be re-examined and adjusted, and the flat ruler and the feeler gauge of the motor are used. The difference between the outer circle, upper, lower, left and right of the coupling shall not exceed 0.15 mm. The deviation between the end faces of the two couplings does not exceed 0.2 mm.

3, do not use the pump to bear the weight of the pipeline, the pipeline should be received by the pipeline support equipment.

4. Press the end of the application to turn the coupling to see if it is easy and flexible, and there is no stuck.

Disassembly

1. Unscrew the four screws that connect the bearing body to the pump body and loosen the mechanical seal and the pump cover.

2. Unscrew the impeller (right-handed) and remove the impeller, key and pump cover, and then remove the mechanical seal from the pump cover.

3. Pull down the coupling with a puller and then remove the key, the bearing end cover, and then disassemble the shaft and bearing.

4. The assembly sequence of the pump is reversed as described above.

5. When reloading the inlet bundle of the suction pump, please note that the water blocking valve should be facing to the front so as to fit the front of the water blocking valve to ensure self-priming effect (see the figure below right).

Mechanical seal installation

1. When replacing the mechanical seal, pay attention to the specifications and the models must match the original ones.

2. During the installation of mechanical seals, it should be kept clean and the seal originals must not be knocked to prevent damage and damage.

3. When installing the size seal valve and the static and dynamic ring, the surface should be coated with a layer of clean oil and transparent oil.

4. Install the static ring and the large apron into the pump cover and then attach them to the shaft (note: the moving ring pin must be aligned with the impeller's drive hole).

5, the bomb seat, the spring, push the composition - body. With the spring seat as the working point, push it onto the main shaft, the thrust of the spring is 2-4mm after the spring is slid on the shaft. If the spring is not compressed, it can slide. It means that the moving ring and the main shaft are loosely loose, and the friction is small. If the spring is contracted more than 6mm, the moving and sealing ring can not slide on the shaft, indicating that the tightening should be tight. To check if the mechanical seal is consistent with the original.

Contact us if you need more details on Tainless Steel Self-priming PumpS. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Safety Explosion-proof Pump、Good Quality Electromagnetic Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Self-priming Pump